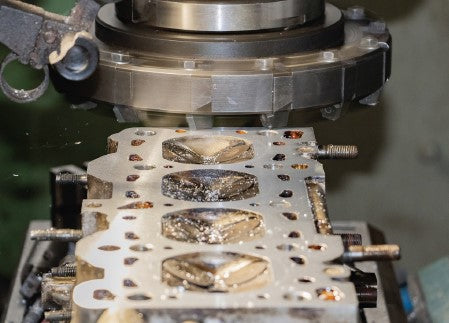

Cylinder Head Surface

Importance of cylinder head surface finish when using metal head gaskets

Permaseal MLS (multi-layer steel) head gaskets are coated in a specialised rubber coating to enable the gaskets to micro seal the engine fluids (coolant and oil).

Due to the rubber coating only being a few microns thick, the metal gasket requires that all the sealing surfaces are completely flat and have a surface finish of less than 0.50 micrometres Ra to perform correctly.

Surface finish or perhaps more correctly surface roughness, is expressed as Ra. The Ra surface roughness is typically measured with a measuring tool called a profilometer.

The profilometer draws a small diamond tipped stylus across the testing surface and the Ra finish is calculated from the surface topography.

So, when installing a Permaseal MLS head gasket, ensure that both the cylinder head and the cylinder block surfaces are clean, flat and have the required surface finish of less than 0.50 micrometres Ra.

Any surface exceeding these values should be re-machined or replaced. And unless specifically stated in the manufactures fitting instructions, no additional sealants or coatings should be applied to the gasket or sealing surfaces.