Why Doesn’t My Head Gasket Stick?

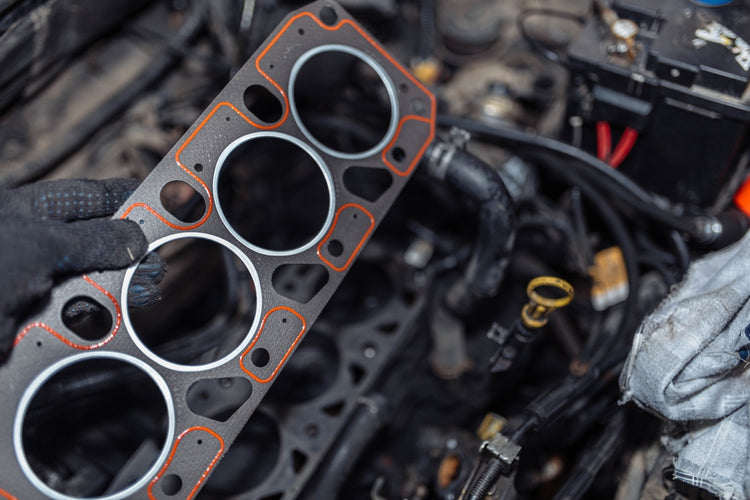

Many composite material head gaskets, manufactured by AA Gaskets, are given an impervious silicone coating, applied during the manufacturing process. This coating improves the micro sealing characteristics. In particular, the cold sealing properties of the gasket during initial start up will seal coolant and oil, provided both the head and block surfaces are clean and within specifications, and the head bolts have been tightened to the correct specification.

The added bonus of using silicon coated head gaskets is their tendency not to stick to the cylinder head and block. Therefore, cleaning of these surfaces is much easier, should the gasket require replacing. This does not mean the gasket has not sealed.

The use of some chemical sealers can cause the silicone coating to deteriorate and, in some cases, it may cause the deterioration of the gasket itself. The added thickness of an applied sealer on a head gasket can prevent the correct torque being applied or cause uneven loading. Chemical sealers are not recommended or required on any AA Gaskets head gaskets