Silicone Beading

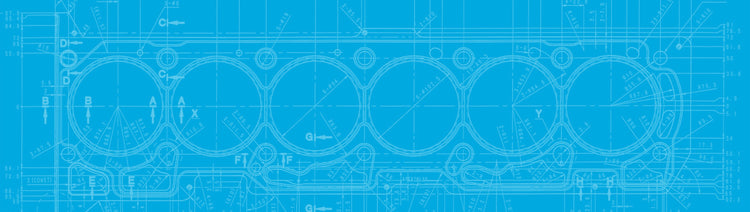

Many of today’s head gaskets have a need for improved sealing. This need has resulted from engine manufacturers design compromises in bolt size, location, quantity, and the (structural and thermal) rigidity of the cylinder block and head.

To improve the sealing characteristics of the gasket, particularly at initial start-up (cold sealing), a bead of sealant is selectively applied to the gasket in critical areas around coolant and oil holes. The added density created by the applied beading increases the clamping loads on the gasket in these selected areas.

![]()

In most instances, the sealing bead is printed on the top face of the head gasket, though this is not mandatory. On some head gaskets, the sealant is applied on the block face side, this is usually the result of various manufacturing constraints. The beading may be applied to either side of the gasket and this does not diminish its effectiveness, as its purpose is to increase density at these critical points.