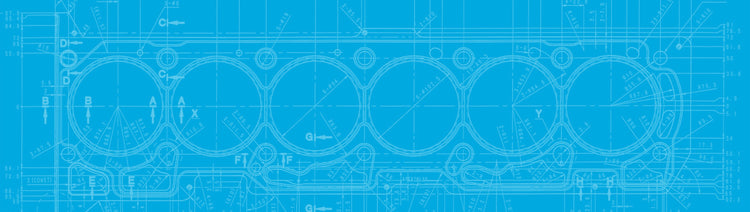

Permaseal Cylinder Head Shins

The various machining operations often involved in the reconditioning of an engine can influence the engine's compression values. An increase in an engine's compression values can cause a condition known as detonation or pre-ignition, which in turn will cause additional heat to be generated in the combustion chamber and overheating can occur. Cylinder head shims are a cost-effective method of restoring compression values, created by the removal of metal from the cylinder block and head faces.

Permaseal cylinder head shims are manufactured from cold rolled mild steel and coated with a zinc phosphate enamel. Available in two grades; 0.8mm and 1.5mm thick; Permaseal cylinder head shims are precision matched to Permaseal head gasket profiles and should not be used in conjunction with another manufacturers head gasket.

To ensure optimum performance from the installation of a Permaseal head shim, both the cylinder block and head surfaces should be flat, clean, dry and free of debris. Using a good straight edge and feeler gauge, check both the cylinder head and block for warpage and flatness. If a gap exceeding 0.051mm (0.002”) can be measured at any point, then the surface will have to be machined. For composite type head gaskets, a surface finish of between 1.0 and 2.5 micrometres Ra (40 to 100 microinches Ra) is required. Unless the engine manufacturer states otherwise, tap all cylinder head bolt holes. Check the condition of all cylinder head bolts and replace any damaged bolts where necessary. Apply a light film of engine oil to the threads and bearing surfaces of the cylinder head bolts during assembly.

Unless otherwise stated, as in the case of the 4.0 Ford EA to EL Falcon engine, the cylinder head shim should always be installed on the engine block surface. To assist with the cold seal of engine fluids a light coating of Three Bond 1211, or equivalent sealant, should be applied to the mating surfaces of the engine and the shim. Do not apply sealant to the mating surfaces of the shim and head gasket.

When using a cylinder head shim, it is important that all cylinder head bolts are retorqued, as the use of sealant will cause a relaxation when temperature is introduced. Bring the engine up to normal operating temperatures for approximately 60 minutes. For aluminium cylinder heads, allow the engine to cool completely, preferably overnight, prior to re tensioning. On cast iron cylinder heads, retention while the engine is still hot. Following the torque sequence completing each bolt before proceeding to the next, back off and retorque the cylinder head bolt continuing in sequence, until all of the cylinder head bolts have been retorqued.