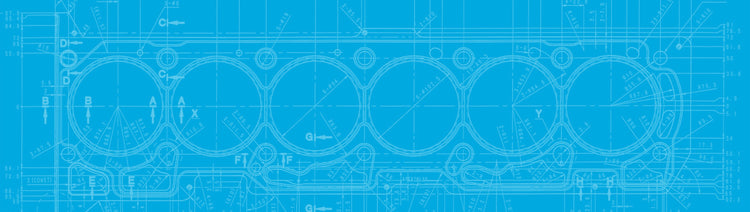

Localised Hotspots

Failure Diagnosis

Replacement of engine gaskets can be time wasted, if the cause of engine failure has not been identified. Gaskets act much like as safety valve or fuse, designed to give way, amid underlying fitting or operational problems, thus preventing more detrimental engine damage. As such, clues left on the gasket may help you diagnose a failure, preventing any re-occurrence.

Hot spots in a cylinder block or head are caused by localised overheating. When a hot spot forms, the surrounding metal expands greatly creating added stress, which may cause the head to warp or even crack. The extreme temperature of a hot spot can also cause a localised soft spot in the cylinder head.

|

A Cooling system that is not operating efficiently, loss or lack of coolant, an air pocket in the cooling system, or an abnormal combustion problem that causes combustion temperatures to increase dramatically, can result in the formation of a localised hot spot. Aluminium cylinder heads where the exhaust valves for the two centre cylinders are positioned back-to-back are also prone to localised overheating between the adjacent sets of valves.

Localised hot spots are one of the more easily identifiable causes of a head gasket failure. A hot spot causes the surrounding metal in the cylinder block and head to expand, which in turn can crush and damage the head gasket, creating a leak where the exhaust gases will erode the gaskets facing material. Eventually, the escaping exhaust gases will burn through the gaskets fire rings and steel core.